Manufacture

Production sites

KEF Japan Production site, Headquarters

Sakura, Chiba Japan

Main production site in Chiba (pictured) and Yamagata, Northern Japan production site

Material making

Mixing roll machine

Mixing roll machine for testing

Pressurized kneader

Feeder extruder (strainer)

Production

Hydraulic molding machine

Injection molding machine (horizontal type)

Injection molding machine (vertical type)

Bi-color different resin injection molding machine

Ultra shot machine

Clean room (Class 1000) cubicle

Test & Measuring for Quality Control

Clean room (Class 1000) cubicle

Oil resistance tester

Low temperature bending tester

Fatigue testing machine

Compression permanent strain tester

Large universal projector

Micro hardness tester (Wallace,UK)

Micro hardness tester (Bareiss,Germany)

Compression test machine

Tool microscope (NIKON / NEXIV)

KEF Shenzhen China production site

Material making

Mixing roll machine

Pressurized kneader

Cutting machine

Production

Hydraulic molding machine

Punching press

Secondary vulcanization oven

Pure water cleaning device

Clean room (class 1000)

Clean bench (class 100)

Clean booth (class 1000)

Clean dryer

Ultrapure water generator

Test & Measuring for Quality Control

Projection testing machine

Tension tester

Hydrometer

Hardness tester

Tool microscope

Curelastometer

KEF Thailand Production site

Material making

Mixing roll machine

Cutting machine(Cutter & Slitter)

Production

Vaccum press molding machine

Test & Measuring for Quality Control

Rheometer

Tool microscope

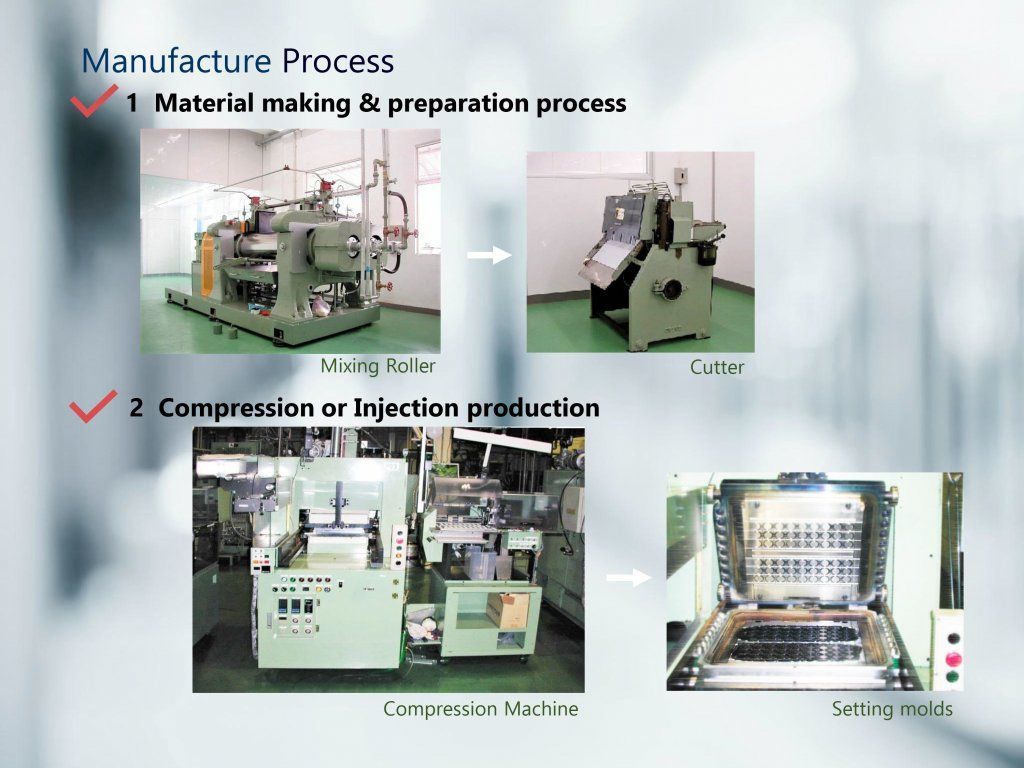

Manufacture Process

Manufacture process consists of 4 main steps;

Material making, production with compression or injection machine, peeling the parts from the produced sheets and quality control.

KEF develops its own Elastomer materials in our R&D section in the engineering team.